Box-build Assembly

Box Build/EMS-Electronic Manufacturing Services

The market demand of Electronic manufacturing services is growing. It refers to a manufacturer that provides a series of services such as manufacturing, procurement, partial design, and logistics for electronic product brand owners.

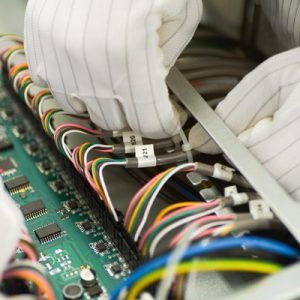

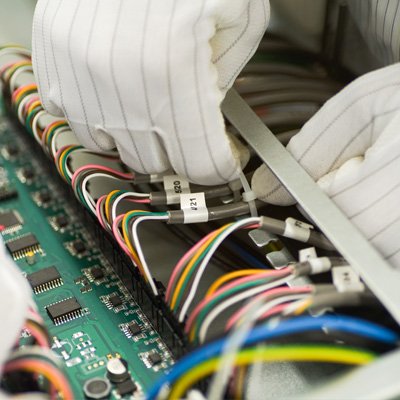

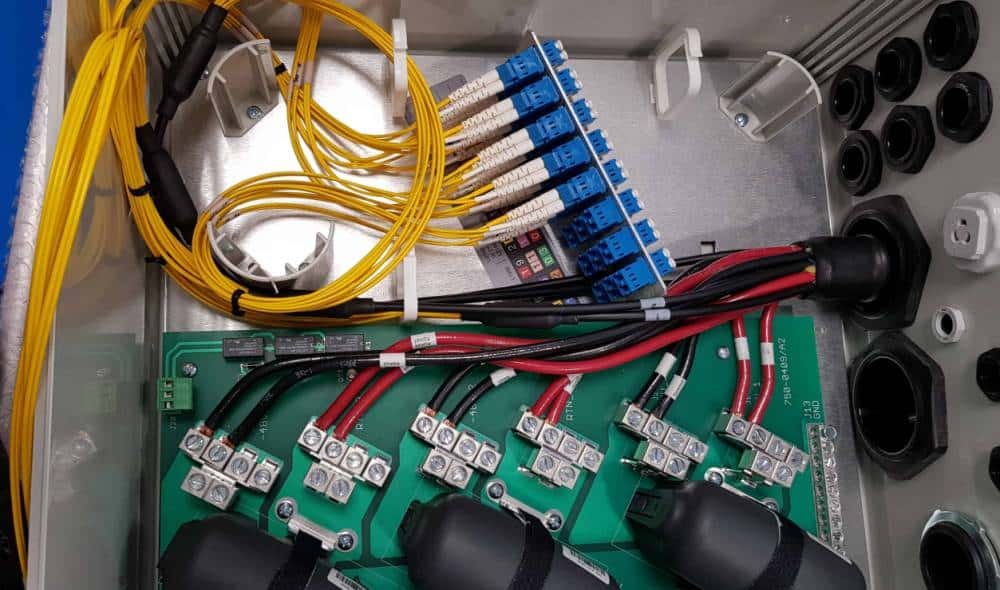

Wonder Tech provides customers with assembly services for finished electronic products, involving industrial controllers, consumer electronics, IoT devices, electronic and electrical equipment, etc. Assembling the PCBA circuit boards that have been produced and tested with the casing, wires, etc., and packaging them as a complete set products then delivering to end customers. Our company has passed the ISO9001:2015 quality management system. During the PCBA assembly process, we strictly implement the SOP operation standards, station self-inspection, QC full inspection, QA sampling inspection, 100% inspection before shipment. At the same time, we adopt barcode management System, effective traceability and registration to distinguish good products from defective products, to achieve the ideal goal of passing rate of assembly and customer quality random inspection.

For different products, customers may have additional steps including software programming, labeling, etc. And if the products are used in extreme weather, we provide conformal coating services that select suitable coating materials to protect them from harsh environments such as humidity, dust and extreme temperatures. Specific areas of the PCB are covered to prevent smearing of sensitive components, connectors or test points.

Additionally, products may undergo burn-in testing or functional and final testing as part of the quality control process. Once assembled, the completed unit can be shipped directly to the customer or returned to the manufacturer for additional packaging or testing.