SMT Assembly

Advanced Surface Mount Technology Support by Wonder Tech

Wonder Tech provides high-end SMT placement processing services for electronics products, equipped with 6 automatic high-speed SMT assembly lines, automatic board loading machines, automatic solder paste printing machines, 3D SPI solder paste machine, multi-temperature zone reflow soldering, AOI machine, X-Ray machine, baking machine, steel mesh cleaning machine, etc., We have provided pcb circuit board processing and manufacturing services for global customers for a long time. We have passed the ISO9001:2015 quality management system and can support the placement of 0201 components, 0.4mm Pitch BGA, QFN and other precision electronic components.

Our SMT Workshop View

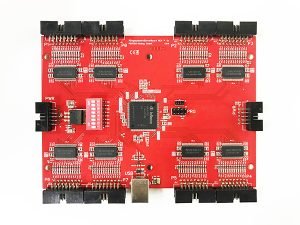

Our PCBA Products

SMT Assembly Capabilities

| SMT Lines | 6 Lines |

| Capacity | 50 million placements per month |

| Max Board Size | 680×500mm Smallest:0.25″x0.25″ |

| Min Component size | 0201 – 54 sq. mm. (0.084 sq. inch), long connector, CSP, BGA, QFP |

| Speed | 0.15 sec/chip, 0.7 sec/QFP |

| Wave-Solder | Max. PCB width:450mm |

| Min. PCB width: no limited | |

| Component height:Top 120mm/Bot 15mm | |

| Sweat-Solder | Metal type :part, whole, inlay, sidestep |

| Metal material:Copper , Aluminum | |

| Surface Finish:plating Au, plating sliver , plating Sn | |

| Air bladder rate:less than20% | |

| Press-fit | Press range:0-50KN |

| Max. PCB size:800X600mm | |

| Quantity | No MOQ, Prototype & Low Volume PCB Assembly,And mass assembly |

| Type of Assembly | SMT and Thru-hole |

| Solder Type | Water Soluble Solder Paste,Leaded and Lead-Free |

| Components | Passives Down to 0201 Size BGA and VFBGA Leadless Chip Carrier/CSP Double-Sided SMT Assembly Fine Pitch to 08 Mil BGA Repair and ReballPart Removal and Replacement-Same Day Service |

| File Formats | Bill of Materials ,Gerber Files, Pick-N-Place File(XYRS) |

| Type of Service | Turn-Key,Partial Turn-Key or Consignment |

| Component Packaging | Cut Tape, TubeReels Loose, Parts |

| Turn Time | Same Day Service to 15 day service |

| Testing | XRAY Inspection ,AOI Testing , ICT,Probe flying,burn-in,function test,temperature cycling. |

Choose Wonder Tech, a professional PCBA manufacturer

- Advanced equipment: PCBA processing and surface mount production require professional equipment, such as high-speed SMT placement machines, multi-temperature reflow soldering, AOI machine, X-Ray machine and other equipment, which Wonder has.

- Professional process management: Wonder Tech has passed ISO9001 quality management system, IPC-A-610E electronic assembly acceptance standards and other certifications. We also have SOP instructions and other documents to guide the behavior of employees. By looking at the documents and qualification certification, you can get a general idea of the strength of our factory’s quality control.

- The workshop environment: Such as dust-free workshops, anti-static measures, etc. SMT PCB assembly has certain requirements for the workshop environment. The more sophisticated products, the higher requirements for the workshop environment.

- Rich experience: Wonder Tech has many years of custom design PCB & PCBA production, has rich electronics assembly cases and has served large customers, such as Samsung.

- Solution & Services: Wonder Tech can provide a complete solution. When customers encounter problems, we can take the initiative to take responsibility, respond quickly, and solve problems for customers.